What is TIG welding?

Argon arc welding is a welding technique that uses argon as a shielding gas. Also known as argon gas shielded welding. It is to pass argon shielding gas around the arc welding to isolate the air from the welding area and prevent the oxidation of the welding area.

The argon arc welding technology is based on the principle of ordinary arc welding. It uses argon gas to protect the metal welding material. Through high current, the welding material is melted into a liquid on the welded substrate to form a molten pool, so that the welded metal and welding A welding technology in which the welding material achieves metallurgical bonding. Because the argon gas is continuously supplied during high-temperature fusion welding, the welding material cannot be in contact with oxygen in the air, thereby preventing the oxidation of the welding material, so it can weld stainless steel and iron hardware.

When you can choose the Economic slow speed TIG steel pipe welding machine/ TIG pipe welding machine?

- When you want to produce pipes but the production rate is not very high.

- When you want to do the investment, but the budget is limited.

- When you want to produce the pipes both of stainless steel and carbon steel.

- When your factory does not have the very professional engineer to run the HF production line.

- When you do not have enough big space of workshop to run HG pipe line.

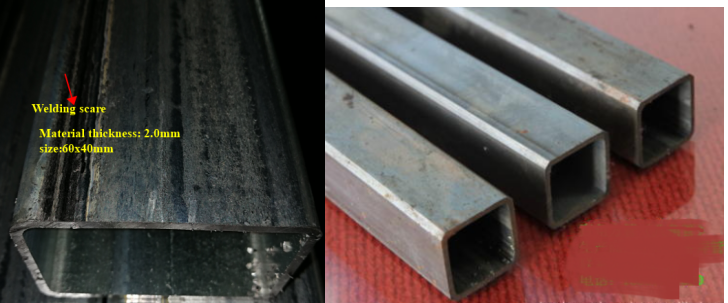

- When you want to produce Fence post like 60x40x2.0mm.

- When you want to produce highway guardrail post and others.

In the following part, we will show more details of this production line.

What is the difference of TIG welding and HF welding from the pipe appearance:

Compared with the HF welding machine, the welding seam made by TIG welding, it is a little wide and dark, not so beautiful like the TIG welding machine.

Take a popular design of Economic slow speed TIG steel pipe welding machine/ TIG pipe welding machine as an example to show how the machine is designed:

Customer requirement:Pipe diameter: 60x40 or diameter round 48mm and 42mm

Material thickness:0.4mm to 2,00

| Machine basic elements | ||

| Decoiler 5 Ton | 1 set | |

| General tube making machine | 1 set | |

| Ultrasonic TIG welder | 1 set | |

| Polishing machine | 1 set | |

| Receiving table | 1 set | |

| Machine working video with TIG welding https://www.youtube.com/watch?v=5-4hQyZiaLo | ||

| Machine Basic Situation | ||

| Working environment: | Temperature: 5-40℃

Humidity: ≤80% |

|

| working speed | 0-12.0M/min

Note: speed will drop as a consequence of the increased thickness |

|

| Production line direction | according to the request of clients | |

| Technological process and equipment introduction:

Uncoil-Forming-Welding-Grinding-Pre-sizing-Sizing&Straightening-Cutting-Conveying roller-End-product shelf |

||

| Roll forming machine function, parameter, structure

Function: Roll forming the stainless steel coil for producing different specification of steel pipe Machine body including steel pipe forming, welding, grinding, sizing four parts Machine tool material: Q235 steel plate, Vibration aging treatment Main panel thickness: 25mm |

||

| Basic parameter:

Horizontal axis diameter: ¢40mm Vertical axis diameter: ¢25mm Bottom diameter of the roller: ¢100mm Forming speed: 5-15m/min Motor power: Main motor 15KW |

||

| Steel Coil Leading-in device

Function: It helps to ensure the centre position and the height of the steel strip when the strip into the forming section Structure: One set of horizontal guiding roller, two sets of vertical guiding rollers, screw rod adjust the distance between vertical rollers for suit the different width of coil, the screw nut can adjust the centre of a set of vertical roller Guiding roller material: Cr12Mov |

||

| Forming segment

6 groups of horizontal rollers holder,7 groups vertical rollers holder |

||

| Forming horizontal roller

Function: install the designed roller for roll forming the steel strip Structure: forming horizontal roller device consists of upper and lower horizontal roller, bearing pedestal, roller stand and adjustment device, the roller shaft can be adjusted up and down solely for suit different pipe diameter Horizontal roller material:40Cr Upper roller adjust through hand wheel |

||

| Forming horizontal roller

Function: install the designed roller for roll forming the steel strip Structure: forming horizontal roller device consists of upper and lower horizontal roller, bearing pedestal, roller stand and adjustment device, the roller shaft can be adjusted up and down solely for suit different pipe diameter Horizontal roller material:40Cr Upper roller adjust through hand wheel |

||

| Vertical roller

Function: Guiding the steel coil go in and prevent the strip rebound in the forming process Structure: consists of vertical roller shaft slider, adjusting screw rod and nut, rack. the screw rod and nut can adjust the distance between vertical roller and axial direction Vertical roller material: 40Cr, cast iron roller stand, surface lacquered |

||

| Steel pipe extruding &welding unit: three groups welding roller

Function: welding the formed pipe Structure: Extrusion device including three sets of extrusion roller, the function of the first extrusion roller is pre-extrude, the second is for welding extrusion, the third is for prevent pipe from cracking after welded ,each set installed on independent roller seat, the centre and distance are adjust by the screw rod ,nut Extrusion roller material: 40Cr |

||

| Steel pipe welding line grinding

Function: Removing the part which is higher than the base metal Structure: containing by three groups of vertical holder and three pieces of automatic grinding wheels, each grinding wheel has an independent electric motor drive, the thrown dust can be centralized collected and it also can be collected after water thrown |

||

| Steel pipe precision sizing:

Consists of four groups of horizontal roller holder and four groups of vertical roller holder and two set of four-roller straightening head Function: according to the requests of product sizing the pipe diameter, make the products meet the tolerance Structure: the structure form of horizontal roller frame and the vertical roller frame as the forming Period, mainly according to the request of technological process |

||

| Four-roller straightening device

Function: Shaping and Straightening the final products Structure: the straightening device has two pairs of roller in front and back, one pair vertical roller One pair horizontal roller, one pair of roller seat is for up and down adjustment, one is for left and Right adjustment |

||

| Material:40Cr,welded rack | ||

| Transmission

Including steel pipe forming part ,welding part, steel pipe outer welding line grinding and steel pipe sizing two parts, individual drive ,the transmission gearbox |

||

| electric motor –2020 gear box - WPA80 /20 reduction gear - universal coupling – horizontal roller shaft, fixed on the same platform base. Adopt alternating current motor, Danfoss frequency converter

Cooling device Function: lubricating & Cooling the roller Structure: pipeline system spraying for each pair of roller Rack lubricating: dry oil |

||

| Single gun welding bracket: 1 set, 6 direction adjusting | ||

| Sizing hydraulic saw cutting machine:

Function: Sizing & cutting the end-products Basic parameter: fretsaw pipe cutter Products specification: ¢12-¢50.8mm Products thickness:0.5-2.0mm Cutting length: ≥2m Cutting accuracy: ±3mm/6m Operating speed:0.5-16.0m/min Saw power: 3.0KW AC Structure: sawing car, lathe bed, drive, drive system, speed detector, fixture, roller device operating table, belt saw cutting Operation mode: manual operation &automatic operation 6 meters output roller &unloading shelf Function: discharging the steel pipe which has been cut by saw, conveying it to the end-product shelf |

||

| 5. Electric control device:

Roller forming machine driving by one set of 7.5KW electric motor, consist of welding grinding part, and steel pipe outer welding line grinding ,steel pipe pre-sizing part , control by Danfoss frequency converter Running temperature:0-45℃ relative humidity: ≤95% |

||

Here is the Economic slow speed TIG steel pipe welding machine/ TIG pipe welding machine working video for your reference:

This above video is for fence post, in the following video, it is for guardrail of highway post:

Next: Steel roll forming machine /pipe forming machine