HG127 Tube Mill for diameter 10-150mm within thcikness 1-5mm

- Summary

The mill is intended for manufacturing of round pipe of Φ20mm-Φ127mm with thickness of 1.5mm–5.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths. Finished product will be of round, square or rectangular pipe.

- The technical flow of the production line

{SteelTape}→→ Single-arbor un-coiler →→Strip-head Cutter and welder→→

Spiral Accumulator→→Forming section(Flattening unit +Main driving unit +Forming unit +Guide unit +High frequency induction welding unit +squeeze roller)+ De-burr frame →→Cooling unit →→ Sizing unit and straightener →→Flying saw under computer-control →→ Run-out table→→straightening

III. Basic conditions:

- a)Steel Pipe Specification

- Round Pipe diameter: Φ76 –Φ127mm

Pipe Thickness: 1.5 – 5.0mm

- Square Pipe: 30X30mm –100X100mm

Rectangle Pipe: 20X40mm –120X80mm

Pipe Thickness: 1.5 – 5.0mm

- Pipe Length: 6.0m – 12.0m

- Length Tolerance: 0-6mm

- b) Steel Tape Specification

- Material: Low Carbon steel (δb≤500Mpa, δs≤235Mpa)

- Steel Tape: Inner diameter: Φ510-610mm

Outer diameter: Max.Φ1800mm

Strip steel width: 120mm-400mm

Strip steel thickness: 1.5mm-5.0mm

The maximum weight: 6.0 tons

- c) Electricity

- Dynamic power: AC380V±10%, 3phases, 50Hz±1.0%

- Control Power: AC220V±10%, one phase, 50 Hz ±1.0%

- d) Electric installed capacity: 900KW

- e) Cooling water

- Reservoir for High Frequency equipment: 30 m³, one set

- Reservoir for circulating cooling water: 25 m³, one set

- f) Compressed air

- Pressure: 0.4Mpa

- Flow: 3.0m3/h

- g) Production capacity

Annual output: 70000 ton, according to the yearly working days, daily working hours and the products.

- h) Line speed: 30-60m/min

- Equipment makeup and main parameters of single unit:

- Hydraulic Single-arbor uncoiler with peeler

1.1. Parameters:

- Coil width: max.400mm

- Coil OD: max. Φ1800mm

- Coil ID: max.Φ508mm

- Coil weight: max. 6.0 tons

1.3. Mandrel expansion by hydraulic

- Five-roll Flattener

2.1 Brief:

There are pairs of nipping and sending roller. Flatten rolls are arranged for two top and three below. Nipping and sending is pressured by hydraulic cylinder, flatter roll motor is cogged by worm wheel and worm screw reduced speed, the worm screws in front and one in back can come true be in-phase by sleeve connecting, which can ensure top leveling roll and under leveling roll be parallel, thereby which reach in the intention of flatten.

2.2 Parameters:

- Quantity of withdrawal roll: 2

- Material of withdrawal roll: 40Cr

- Quantity of flattener roll: 5

- Flattener Speed: 10m/min

- Rigidity of Roller: HRC50-60

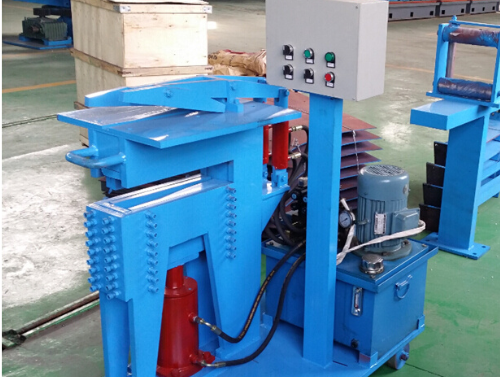

- Shearing & butt welding machine

3.1 Hydraulic shearing parameters machine:

- Cutting by hydraulic system

- Width: ≤400mm

- Thickness: ≤ 5.0mm

3.2 Butt welding machine by manual

- welding machine

More pictures of the HG127 Tube Mill for diameter 10-150mm within thcikness 1-5mm

Next: HG50 Contruction pipe roll forming steel pipe machine