Welded square pipe roll forming machine/tube making machine

Basic information of Welded Pipe Roll Forming Machine:

The mill is intended for manufacturing of round pipe of Φ38mm-Φ102mm with thickness of 1.0mm–5.0mm from cold-rolled and hot-rolled coil strip by means of unclosed tubular blank with its subsequent welding into tube, edge heating by means of solid state high-frequency welder, longitudinal seam welding in rolls of tube welding machine, cooling, further sizing or shaping and on-stream cutting of endless tube in measured lengths. Finished product will be of round, square or rectangular pipe.

welded square pipe roll forming machine features:

1.Take continuous production,there is no need to change the rollers in rough-forming section.

2.The quality mill is reliable in the welding seam technology.

3.The pipe produced by welded pipe mill covers most ss pipes which are currently used by build construction.

4.Straight seam welded pipe mill shares outstanding advantages such as low production cost and high production capacity.

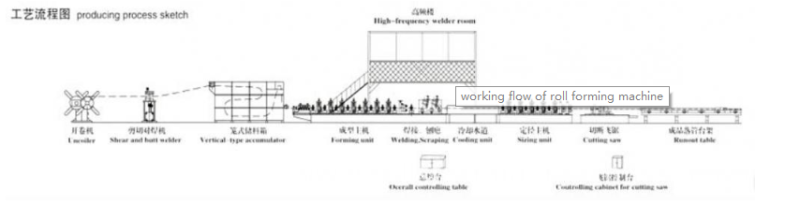

Working flow in chart:

5. Making different types pipes easily as it can change pipe molds in a few hours.

Main technical parameters:

Double head Decoliler

coil inner diameter:450-550 mm

coil max width:300 mm

max carrying capacity: 1500 kg

Usage: It is used to support the steel coil and uncoil it in a turntable way. Passive uncoil pulled by roll forming system

Leveling system:

Usage:Put the raw material(steel plate) through the beach to manufacture and

process,it can guarantee that the products are neat, parallel and everything is uniformity.

Please refer to the equipment regulation to know the function of locate angle iron.

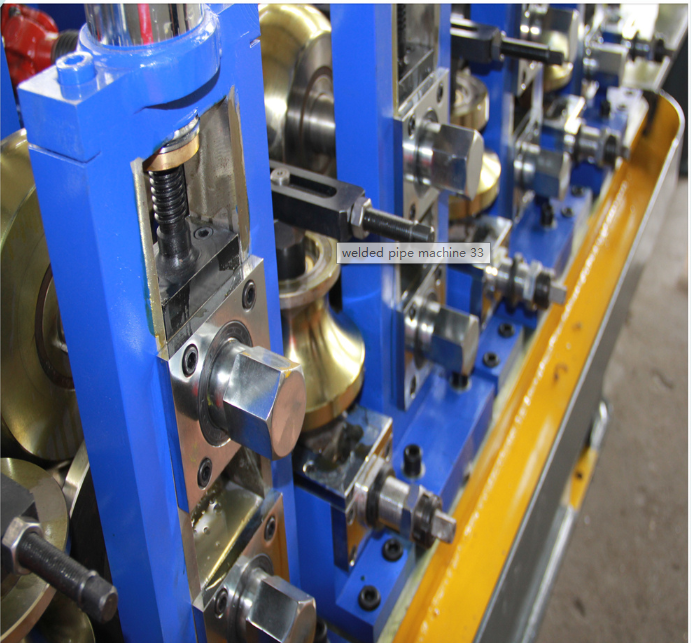

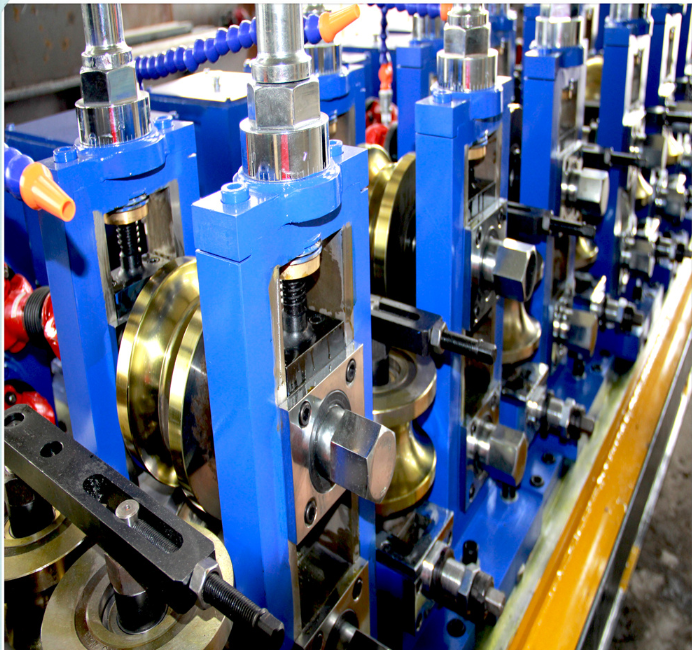

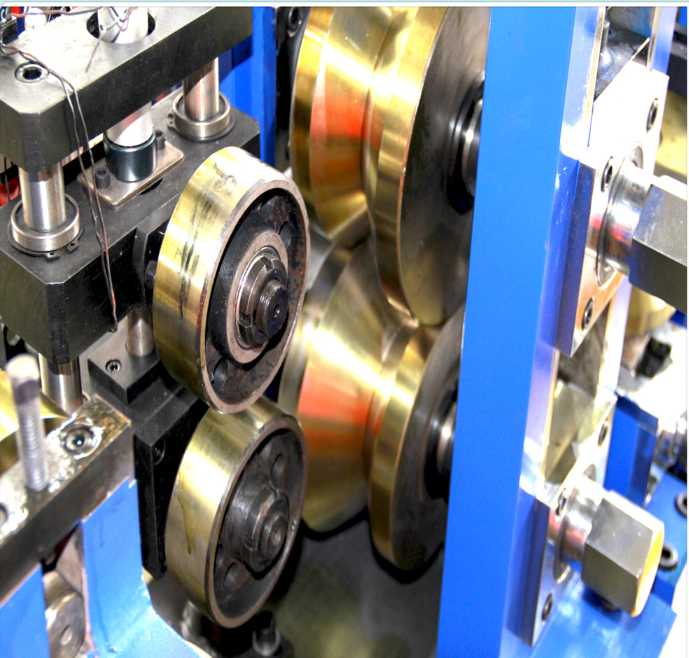

Main roller system:

1.Shaft material & rollers material & shaft diameter45# steel adjustable treatment; 45# steel, polished, plate of chrome 0.05mm; 60mm 2. power: 101kw 3. Transport; Motor; chain drive 4. Forming speed; 20m/min Usage: In order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission,roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is being stamped.

Material: blade, puncher and mold material: Cr12 steel with quenched treated 60-62

Shearing system

Cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor. It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products. Material of blades: Cr12 quenched Power supply : hydraulic power Components:It contains one set of blade, one hydraulic tank and one cutter machine.

Package:

Straight welded pipe mills package Wiped Anti Rust Oil, Rollers and Shafters covered by waterproof film,Hydraulic station, PLC control Box, Spare parts and some small parts packed in plywood box. All Components Fixed by steel wire with Container.

Warranty

1). One year, and we will provide the technical support for the whole life.

2).Training: the buyer should charge of visa, return ticket, food and accommodation overseas

and USD50/person/day for salary.

3). Need one technicians

4).Training time: one week (contains the time of installation and adjustment) The following picture is about shipping scene.